- Home »

- Products »

- Spun-Lace Nonwoven »

- Home

- About

- Products

- Products

- Spun-Bond (Sss) Fabric

- Spunmelt (Ssmms) Fabric

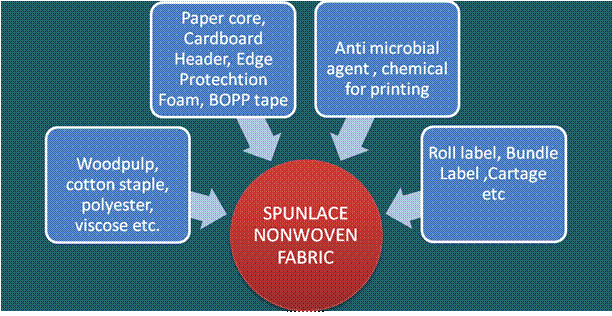

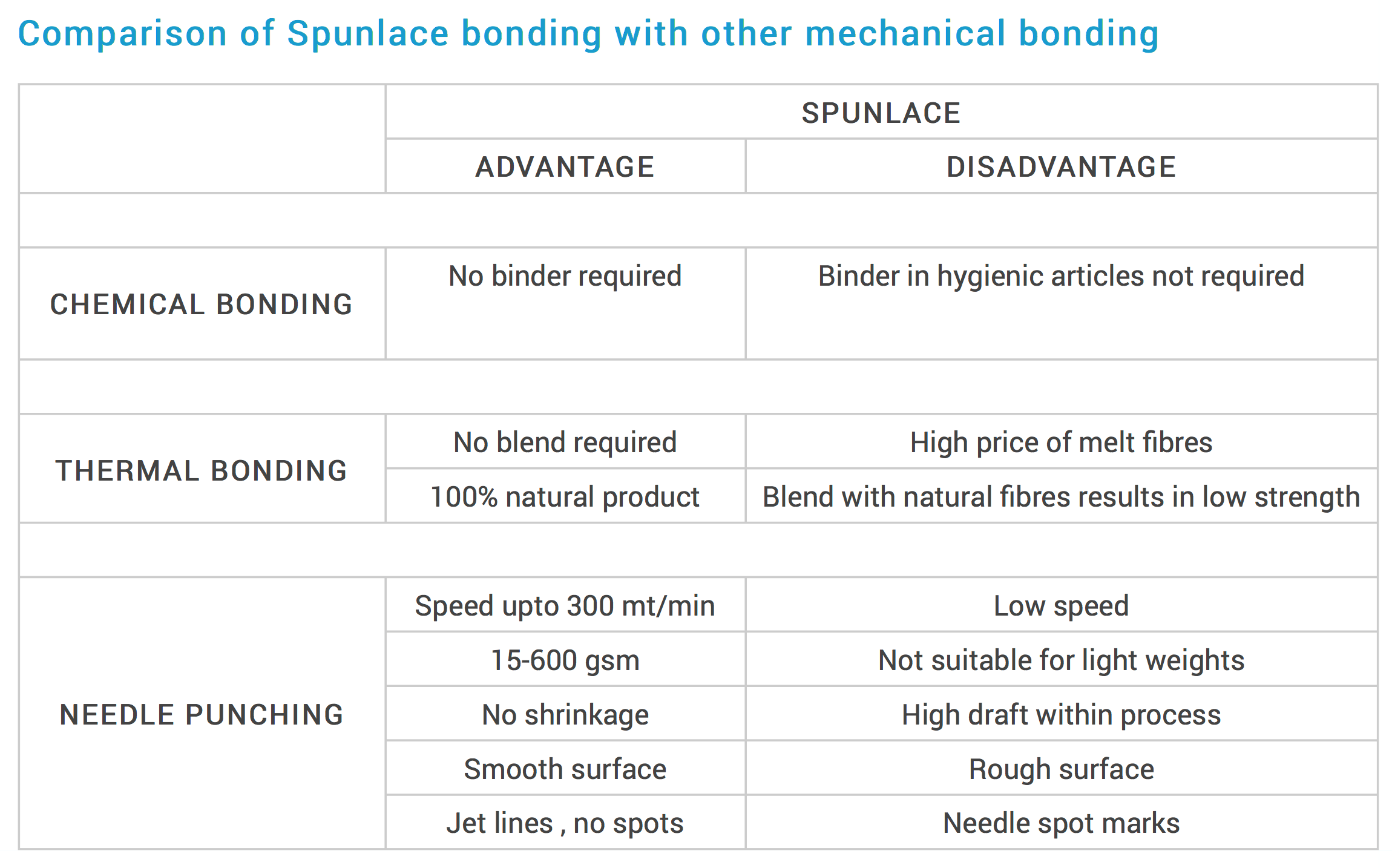

- Spun-Lace Nonwoven

- Personal Care

- Para-Pharmaceutical & Hygiene Care

- Mother & Baby-Care

- Mother & Baby-Care

- Baby Wipes

- Baby Diapers

- SOAPS, DETERGENTS & HOME CARE

- SOAPS, DETERGENTS & HOME CARE

- Antibacterial Soap

- Beauty Soap

- Laundry Soap

- Largo Liquid

- Dish Washing Liquid

- Hand Soap

- Antiseptic Liquid

- Health Care

- Health Care

- Inhaler Wipes

- Meditech Products

- Men Care

- Travel & Convenience

- MOTOR CARE

- Pet Care

- Pet Care

- Pets Body & Paw sanitizing Wipes

- FMCG

- Brands

- Brands

- Our Brands

- Our Brands

Wipo

Wipo Clean Wipo

Clean Wipo

- Partner Brands

- Companies

- Companies

Niche

Niche Nautical

Nautical AK Holding

AK Holding

- Consultancy

- Private Label

- Careers

- Contact